Coating Ru-Flex PVC

Solid gray, black or white rolled PVC coating with a smooth surface. The coating adheres well to all pre-insulated cylindrical surfaces.

moreCoating Ru-Flex METAL

Made of aluminum foil with fiberglass mesh. Designed for use in the production of reflective insulation, foil insulation and other technical purposes. Provides protection against mechanical damage.

moreCoating Ru-Flex ALU

Is a five-layer material of three layers of aluminum foil with a thickness of 9 microns each and two layers of PET film with a thickness of 20 microns each. Ru-Flex ALU is used as a covering layer on internal and external engineering systems, providing protection against mechanical damage and exposure to ultraviolet radiation.

moreCoating Ru-Flex PROM ALU

Is a combined material of PVC with a thickness of 270 microns, aluminum foil with a thickness of 9 microns and PET film with a thickness of 21 microns. It is intended for use as a cover layer of thermal insulation on objects located in the open air, rooms and tunnels.

moreCoating Ru-Flex PROM FORM

Composite material made of fiberglass, laminated with aluminum foil. It is used as a covering layer on objects located in rooms and tunnels. Provides protection against ultraviolet radiation and mechanical stress.

moreCoating Ru-Flex PROM POLYMER

It is used as a covering layer on objects located outdoors and exposed to increased exposure to aggressive environmental factors. Provides protection against ultraviolet radiation, aggressive environment, mechanical damage.

moreRu-flex angle tube

A ready-made technical solution that allows you to reduce the time of installation of insulation in difficult sections of the pipeline, is made on the basis of materials Ru-Flex ST, Ru-Flex VT, Ru-Flex EKO PHARM.

moreRu-flex T-tube

A ready-made technical solution that allows you to reduce the time of installation of insulation in difficult sections of the pipeline, is made on the basis of materials Ru-Flex ST, Ru-Flex VT, Ru-Flex EKO PHARM.

moreRu-Flex ECO PHARM

Technical thermal insulation based on foamed synthetic rubber, intended for surfaces with positive and negative temperatures, is used for objects with increased environmental safety requirements.

moreRu-Flex CRYO

Technical thermal insulation based on foamed synthetic rubber, intended for pipelines with positive and negative temperatures, except for facilities with increased requirements for the toxicity of combustion products

moreRu-Flex BP

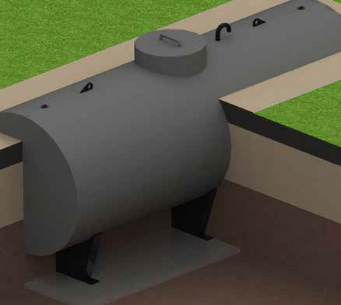

Technical thermal insulation based on foamed synthetic rubber, intended for thermal insulation during ductless laying of pipelines in an underground or overground method.

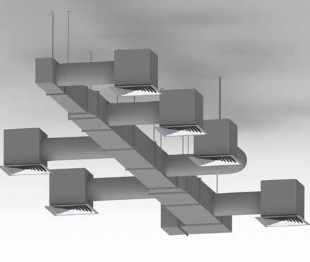

moreRu-Flex VENT-SK

Thermal insulation material, with a self-adhesive coating applied in the factory, intended for insulation of ventilation and air conditioning systems (taking into account the permissible temperature range)

moreRu-Flex VT

Thermal insulation material designed to insulate surfaces with a temperature range from -200 to +150 °C.

moreRU-FLEX Cleaner

Used during installation to prepare the surfaces to be bonded, to dilute the thickened glue.

moreRU-FLEX 454 glue

One-component contact adhesive is designed for bonding heat-insulating materials and RU-FLEX coatings to each other and to metal.

moreRu-flex ST

Technical heat-insulating material intended for the insulation of surfaces with a temperature range from -200 to +110 ° C, with the exception of objects with increased requirements for the toxicity of combustion products

more

Coating Ru-Flex PVC - is a gray, black or white hard rolled PVC coating with a smooth surface. The coating adheres well to all pre-insulated cylindrical surfaces. It does not stretch during use, it serves as a reliable protection of thermal insulation from mechanical damage and gives it an aesthetic appearance.

Coating Ru-Flex PVC - is a gray, black or white hard rolled PVC coating with a smooth surface. The coating adheres well to all pre-insulated cylindrical surfaces. It does not stretch during use, it serves as a reliable protection of thermal insulation from mechanical damage and gives it an aesthetic appearance.

Coating Ru-Flex METAL is made of aluminum foil with reinforced glass mesh. It is intended for use in the production of reflective insulation, foil insulation and other technical purposes. Provides protection against mechanical damage.

Coating Ru-Flex METAL is made of aluminum foil with reinforced glass mesh. It is intended for use in the production of reflective insulation, foil insulation and other technical purposes. Provides protection against mechanical damage.

Coating Ru-flex ALU Is a five-layer material of three layers of aluminum foil with a thickness of 9 microns each and two layers of PET film with a thickness of 20 microns each. Ru-Flex ALU is used as a covering layer on internal and external engineering systems, providing protection against mechanical damage and exposure to ultraviolet radiation.

Coating Ru-flex ALU Is a five-layer material of three layers of aluminum foil with a thickness of 9 microns each and two layers of PET film with a thickness of 20 microns each. Ru-Flex ALU is used as a covering layer on internal and external engineering systems, providing protection against mechanical damage and exposure to ultraviolet radiation.

Coating Ru-Flex PROM ALU Is a combined material of PVC with a thickness of 270 microns, aluminum foil with a thickness of 9 microns and PET film with a thickness of 21 microns. It is intended for use as a cover layer of thermal insulation on objects located in the open air, rooms and tunnels. Provides protection against mechanical damage and exposure to ultraviolet radiation, protects against atmospheric influences.

Coating Ru-Flex PROM ALU Is a combined material of PVC with a thickness of 270 microns, aluminum foil with a thickness of 9 microns and PET film with a thickness of 21 microns. It is intended for use as a cover layer of thermal insulation on objects located in the open air, rooms and tunnels. Provides protection against mechanical damage and exposure to ultraviolet radiation, protects against atmospheric influences.

Coating Ru-Flex PROM FORM - A composite material made of fiberglass, laminated with aluminum foil and intended for use as a covering layer on objects located in rooms and tunnels. Provides protection against ultraviolet radiation and mechanical stress.

Coating Ru-Flex PROM FORM - A composite material made of fiberglass, laminated with aluminum foil and intended for use as a covering layer on objects located in rooms and tunnels. Provides protection against ultraviolet radiation and mechanical stress.

Coating Ru-Flex PROM POLYMER - the polymer coating is intended for use as a covering layer on objects located outdoors (as well as indoors and in tunnels) and exposed to increased exposure to aggressive environmental factors, including the marine atmosphere (shipbuilding, offshore oil platforms, floating refineries). Provides protection against ultraviolet radiation, aggressive environment, mechanical damage.

Coating Ru-Flex PROM POLYMER - the polymer coating is intended for use as a covering layer on objects located outdoors (as well as indoors and in tunnels) and exposed to increased exposure to aggressive environmental factors, including the marine atmosphere (shipbuilding, offshore oil platforms, floating refineries). Provides protection against ultraviolet radiation, aggressive environment, mechanical damage.

Ru-flex angle tube - ready-made technical solution that allows you to reduce the time of installation of insulation on difficult sections of the pipeline. It is recommended to carry out installation using Ru-Flex 454 glue.

Ru-flex angle tube - ready-made technical solution that allows you to reduce the time of installation of insulation on difficult sections of the pipeline. It is recommended to carry out installation using Ru-Flex 454 glue.

Ru-flex T-tube - ready-made technical solution that allows you to reduce the time of installation of insulation on difficult sections of the pipeline. It is recommended to carry out installation using Ru-Flex 454 glue.

Ru-flex T-tube - ready-made technical solution that allows you to reduce the time of installation of insulation on difficult sections of the pipeline. It is recommended to carry out installation using Ru-Flex 454 glue.

Ru-flex ECO PHARM - technical thermal insulation intended for surfaces with positive and negative temperatures (taking into account the permissible temperature range) is used for objects with high environmental safety requirements.

Ru-flex ECO PHARM - technical thermal insulation intended for surfaces with positive and negative temperatures (taking into account the permissible temperature range) is used for objects with high environmental safety requirements.

Ru-Flex CRYO - Modern thermal insulation material, designed specifically for use in air conditioning and refrigeration systems. Ru-Flex CRYO is produced in the form of tubes that are wound into coils. This design allows you to measure and use the required amount of material with a minimum number of joints. Installation in this case does not create waste, reduces the consumption of glue and tape.

Ru-Flex CRYO - Modern thermal insulation material, designed specifically for use in air conditioning and refrigeration systems. Ru-Flex CRYO is produced in the form of tubes that are wound into coils. This design allows you to measure and use the required amount of material with a minimum number of joints. Installation in this case does not create waste, reduces the consumption of glue and tape.

Ru-flex BP - advanced thermal insulation material, it is recommended for thermal insulation of pipelines with positive and negative temperatures and shaped products to them, laid underground or aboveground, as well as for thermal insulation of welded joints of pipelines, shut-off and control valves, mud filters, etc.elements of pipelines as a thermal insulation layer in the construction of thermal insulation.

Ru-flex BP - advanced thermal insulation material, it is recommended for thermal insulation of pipelines with positive and negative temperatures and shaped products to them, laid underground or aboveground, as well as for thermal insulation of welded joints of pipelines, shut-off and control valves, mud filters, etc.elements of pipelines as a thermal insulation layer in the construction of thermal insulation.

Ru-Flex VENT-SK - thermal insulation material, with a self-adhesive coating applied in the factory, intended for insulation of ventilation and air conditioning systems (taking into account the permissible temperature range). It is used at temperatures from -30 to +85 °C. Ru-Flex VENT-SK is non-toxic and is allowed for use in rooms with high sanitary requirements.

Ru-Flex VENT-SK - thermal insulation material, with a self-adhesive coating applied in the factory, intended for insulation of ventilation and air conditioning systems (taking into account the permissible temperature range). It is used at temperatures from -30 to +85 °C. Ru-Flex VENT-SK is non-toxic and is allowed for use in rooms with high sanitary requirements.

Ru-Flex VT (High temperature) - thermal insulation material designed to insulate surfaces with a temperature range from -200 to +150 °C. Ru-flex VT high-temperature thermal insulation is used to prevent heat loss, protect against condensation and corrosion. Due to the closed cellular structure, it has low thermal conductivity and water absorption – it does not absorb or accumulate moisture. When used in rooms with high humidity and condensation does not require waterproofing due to the low coefficient of vapor permeability.

Ru-Flex VT (High temperature) - thermal insulation material designed to insulate surfaces with a temperature range from -200 to +150 °C. Ru-flex VT high-temperature thermal insulation is used to prevent heat loss, protect against condensation and corrosion. Due to the closed cellular structure, it has low thermal conductivity and water absorption – it does not absorb or accumulate moisture. When used in rooms with high humidity and condensation does not require waterproofing due to the low coefficient of vapor permeability.

RU-FLEX sealant - Used for sealing the joint seams of RU-FLEX coatings.

RU-FLEX sealant - Used for sealing the joint seams of RU-FLEX coatings.